Tubular Scaffolding Systems

Product Details:

- Product Type Scaffolding Props

- Material Aluminum, Steel

- Components Other

- Surface Treatment Hot Dip Galvanized, Pre-Galvanized

- Application Construction

- Click to View more

Tubular Scaffolding Systems Product Specifications

- Hot Dip Galvanized, Pre-Galvanized

- Scaffolding Props

- Other

- Construction

- Aluminum, Steel

Tubular Scaffolding Systems Trade Information

- 1000 Per Week

- 7 Days

- as per requirement

- All India

- ISO 9001:2000 Certified ,

Product Description

Tubular Scaffolding Systems

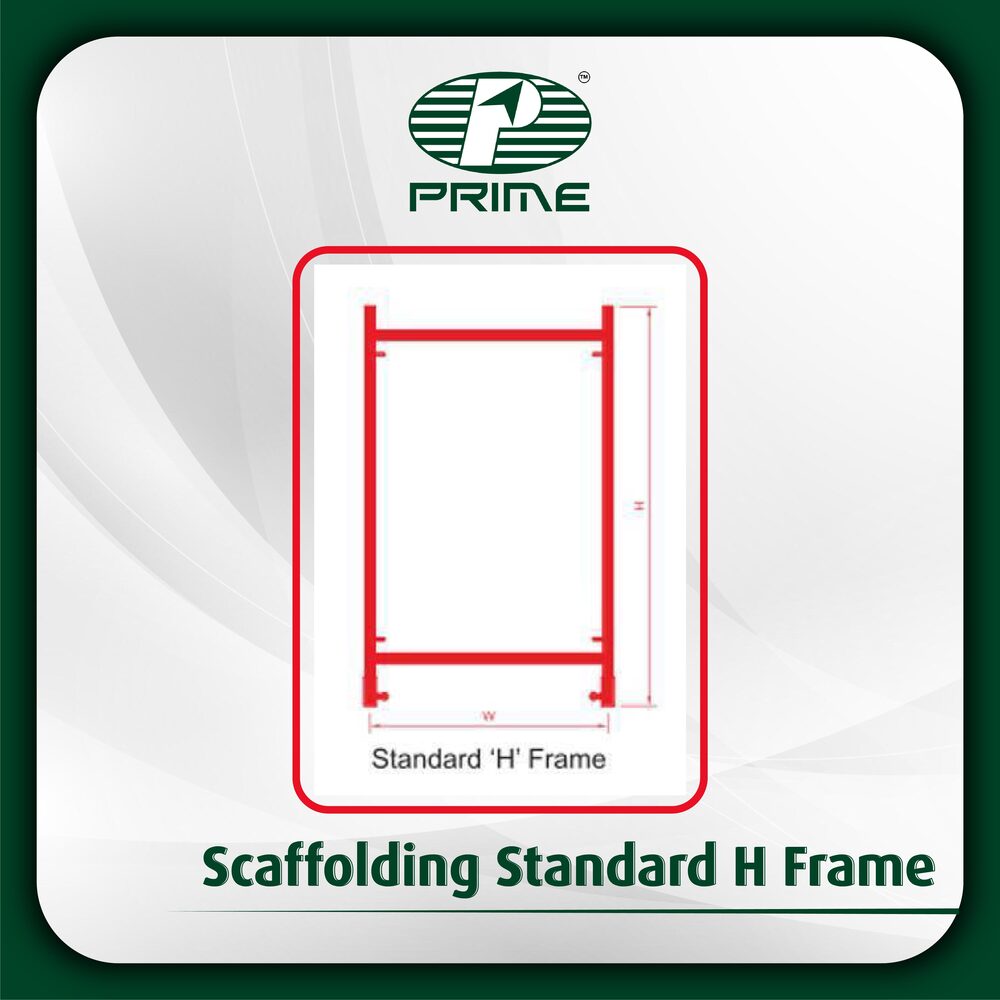

Sub-category: Scaffolding Systems

Category: Scaffolding

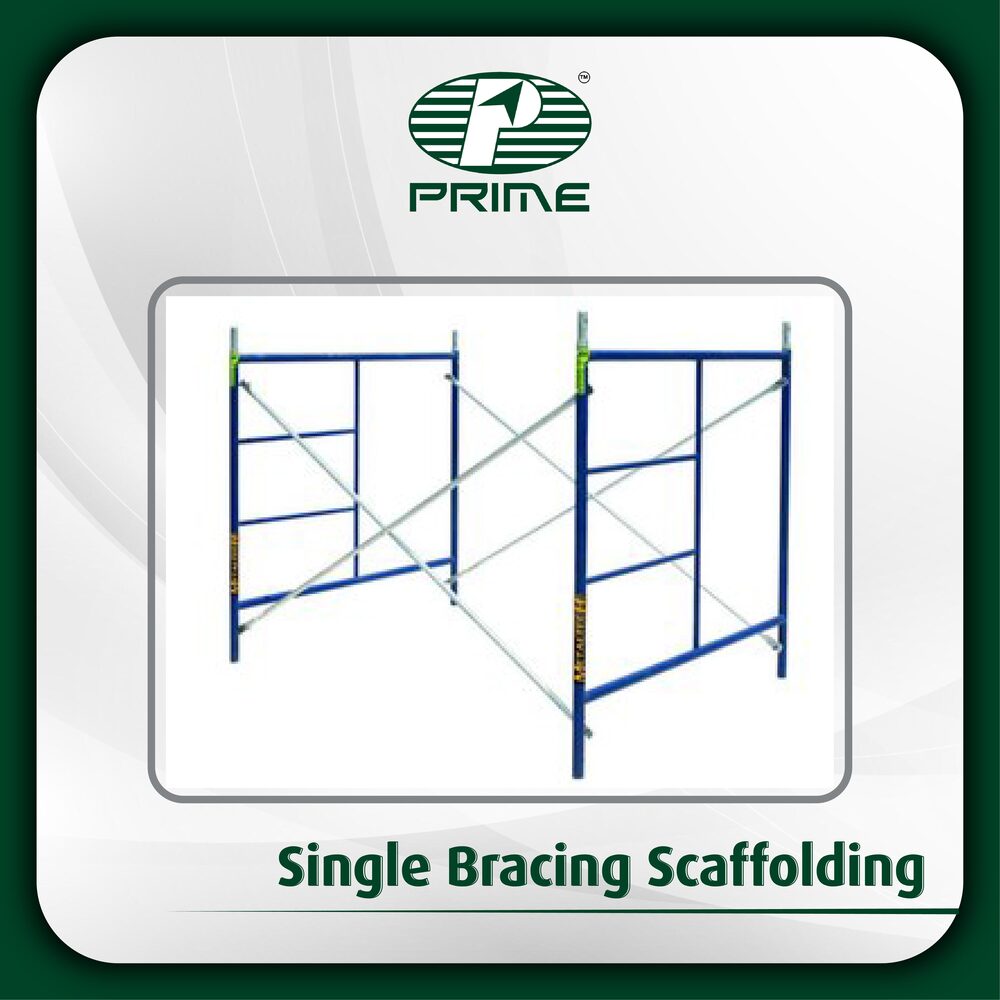

PRIME STEELTECH (I) PVT. LTD. is a leading manufacturer, exporter, and supplier of high-quality Tubular Scaffolding Systems designed to meet the dynamic needs of the construction and infrastructure sectors. Built from durable, high-tensile steel tubes, our scaffolding systems provide robust support, easy assembly, and safety compliance, making them ideal for demanding industrial applications.

As a trusted name in the scaffolding industry, we offer precision-engineered Tubular Scaffolding Systems that cater to civil construction, commercial building projects, industrial plant maintenance, bridge and flyover construction, refineries, and shipbuilding yards. Our products meet international safety standards and are suitable for both temporary and long-term use.

… Key Features:

-

Manufactured using standardized high-strength steel tubes

-

Hot-dip galvanized or painted surface finish for corrosion resistance

-

Compatible with a wide range of scaffolding fittings and accessories

-

Lightweight yet strong for easy transport and setup

-

Ideal for formwork support, wall access, and elevated work platforms

ðŸ—ï Applications:

-

Infrastructure development projects

-

Industrial construction and maintenance

-

High-rise building scaffolding

-

Metro, rail, and road projects

-

Oil & gas, power plants, and chemical units

At PRIME STEELTECH (I) PVT. LTD., we are committed to serving B2B clients, including contractors, construction firms, scaffolding rental agencies, and infrastructure developers, with reliable and cost-effective Tubular Scaffolding Systems that enhance efficiency, safety, and productivity on-site.

📠Bulk orders, custom configurations, and timely delivery available. Partner with a leading manufacturer, exporter, and supplier for your scaffolding system needs”PRIME STEELTECH is your dependable choice in the global scaffolding industry.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Scaffolding System' category

|

PRIME STEELTECH (I) PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |